Homogeneous Belts and Profiles

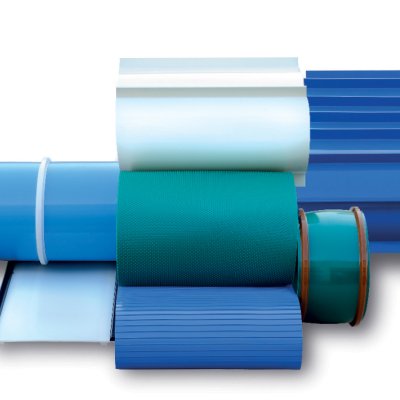

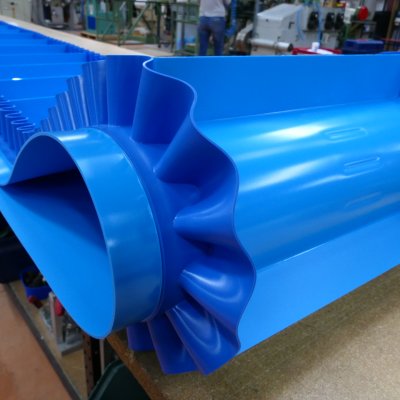

Production technology of extrusion and calendaring, quality raw materials, together with continuous quality control is reflected in a wide range of high-quality products. Fabrication enables combining basic materials with a wide range of accessories. Final products successfully address issues of hygiene, mechanics, chemical resistance, and ecology. Belts and profiles are made of elastomeric, heat-weldable polyurethane materials and polyester. They are available in many hardness variations. They are distinguished by their high elasticity and tensile strength. Extensive ranges of standard variants, but also a wide range of atypical profiles and belts cover a wide range of industrial applications.

Low Maintenance Costs

- Homogeneous belts and profiles allow simple and fast on-site splicing without the need for dismantling sets and machines.

- Repairs can be handled very flexibly and immediately, resulting in low downtime.

- Repair technologies enable simplified logistics and low inventory levels.

High Operational Efficiency

- A wide range of materials in different hardnesses allows applications to be tuned for maximum performance, shapes, surfaces, and accessories.

- Durability, compared to the layered construction of synthetic conveyor belts, is greatly enhanced by a range of mechanical resistance, abrasion and cut or chemical resistance properties against oils, fats, and solvents.

- To ensure maximum load capacity, a range of products is available with integrated polyester, aramid, steel, or stainless-steel cords.

Food Safety

- Homogeneous, monolithic construction exhibits a high level of resistance to chemicals, animal and vegetable oils and fats.

- Easy-to-clean surface significantly reduces the consumption of detergents.

- Homogeneous belts and profiles meet all European and international standards, rules and regulations for materials suitable for direct contact with food.

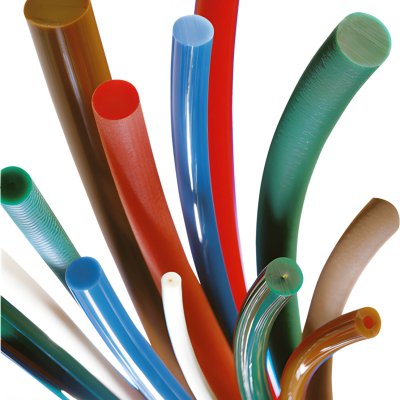

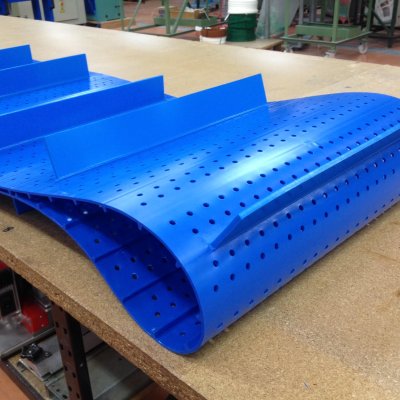

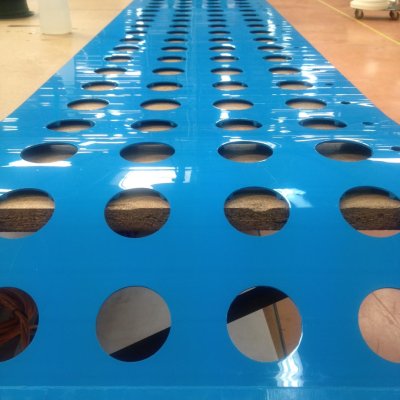

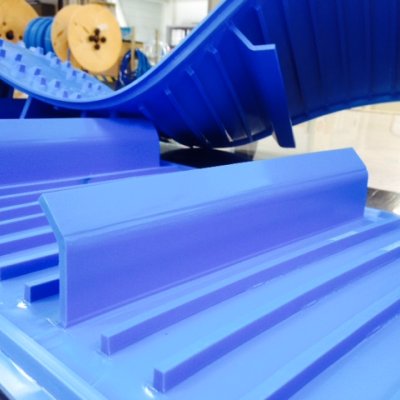

Homogeneous Profiles

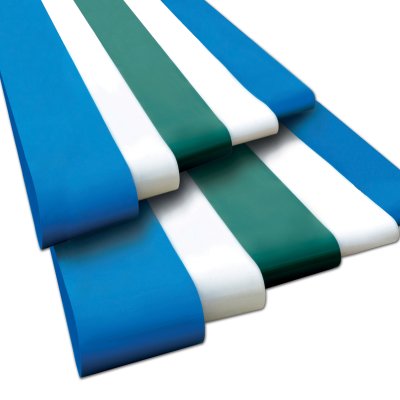

A range of round, V-belt, V-belt ridge belts as well as atypical belts are designed for conveying applications or optimal power transmission with long service life in demanding conditions.Monolithic Conveyor Belts

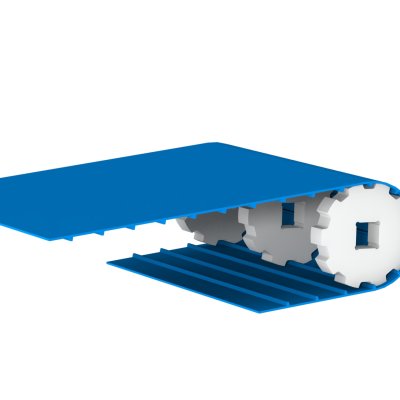

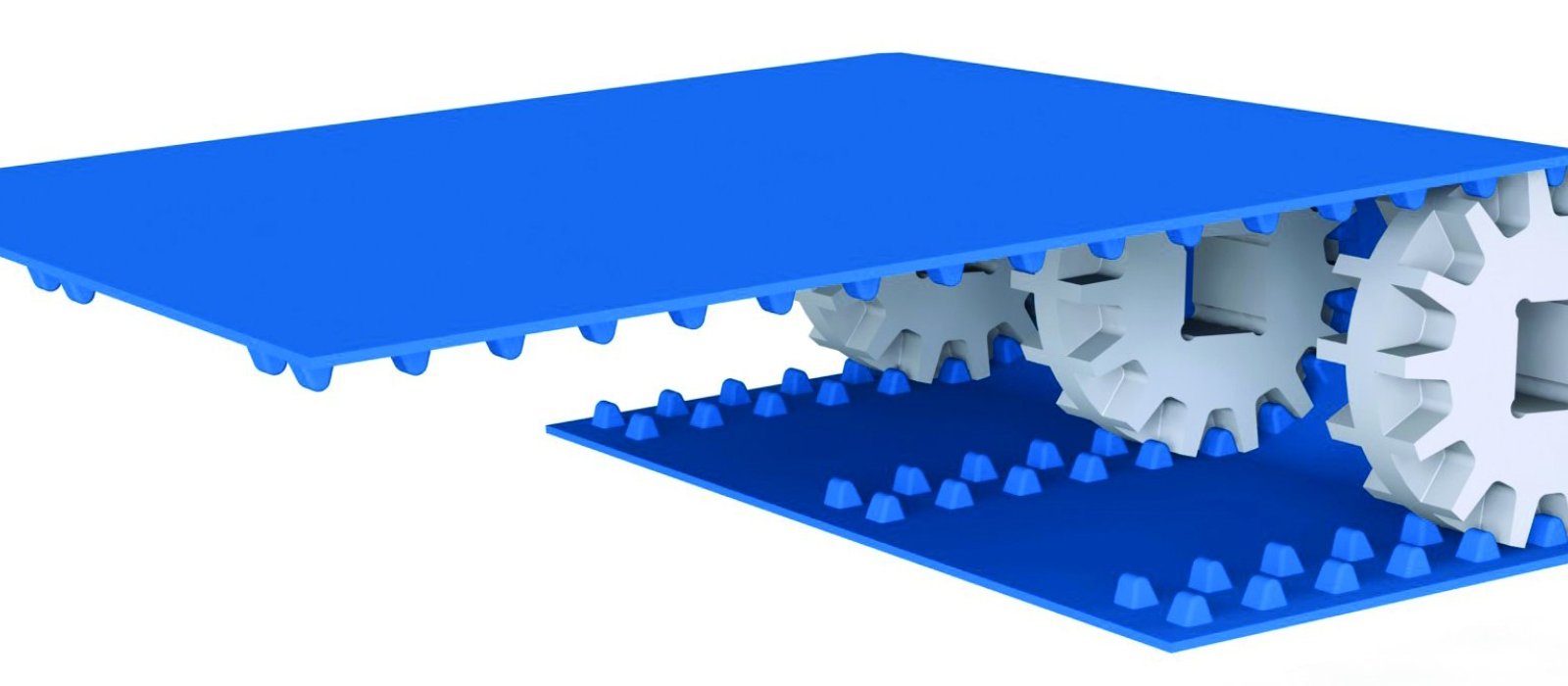

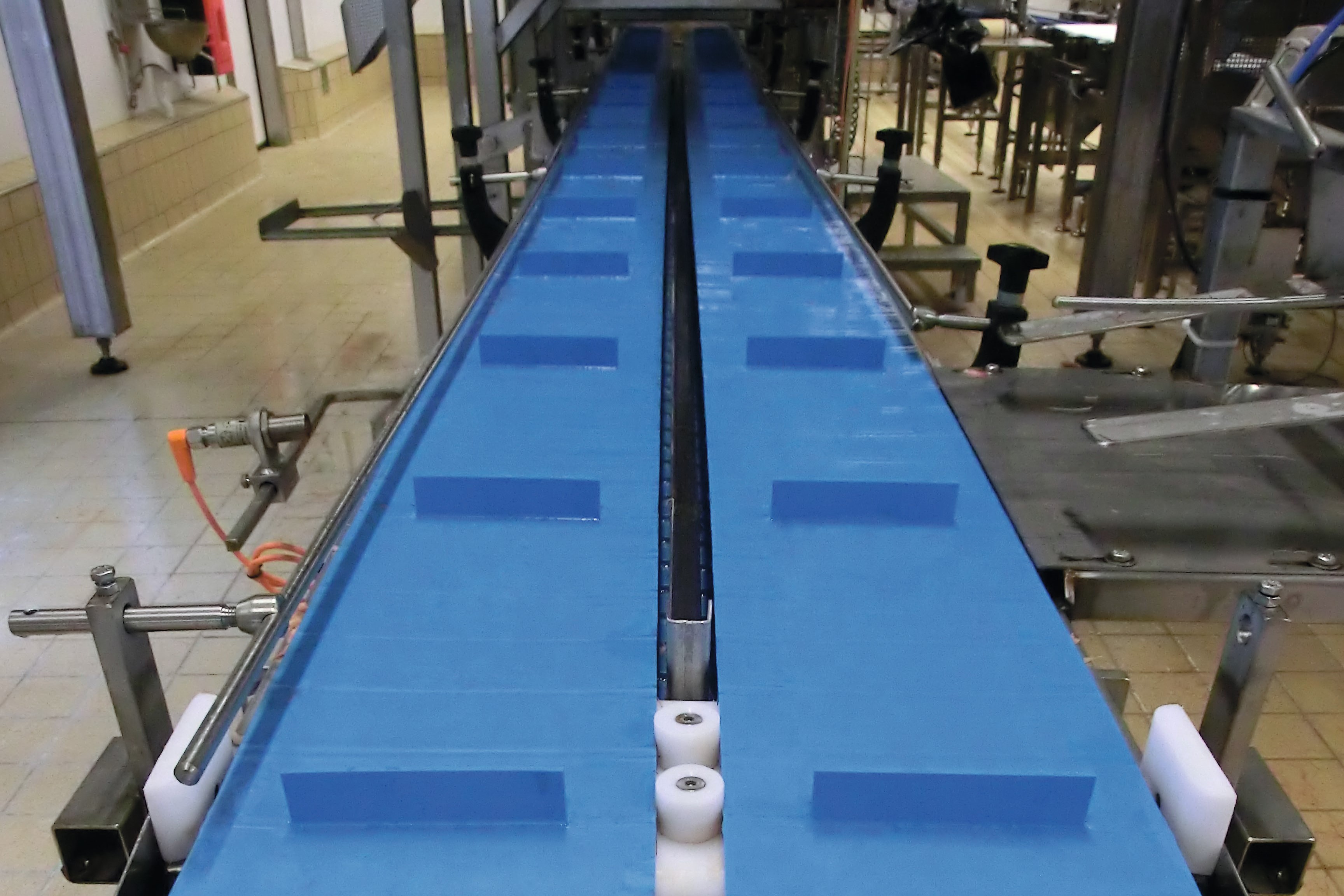

Traditional, flexible, and economical products, for normal conveying applications rely on friction between the belt bottom side and the drum for power transmission. They have the hygienic advantages of a monolithic thermoplastic structure.Positive Drive Conveyor Belts

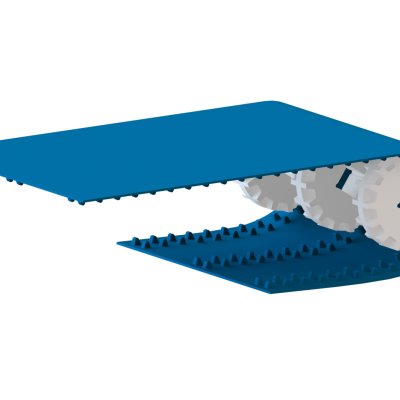

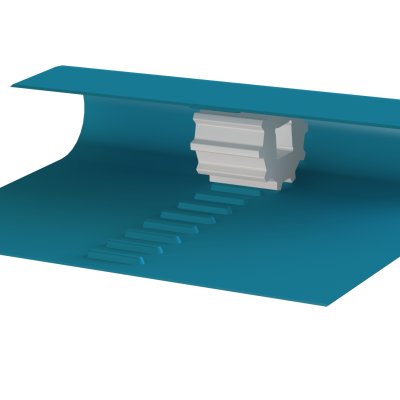

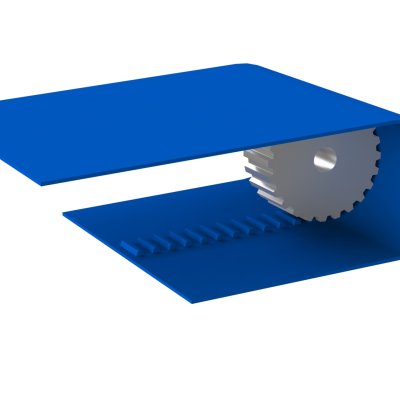

Direction and speed of movement, precise positioning, and correct orientation rely on direct, positive drive products capable of synchronized processes. They eliminate tensioning, guiding, alignment, and cleaning problems.- DEL/DRIVE - the ideal alternative to modular applications, teeth across the full-width

- POSITIVEBELT - self-centring belt with positive drive, double rows of teeth

- S/DRIVE - standard belt with positive drive, one or two rows of teeth

- DEL/SYNC - synchronous transport with extreme precision, centrally located teeth

Accessories

- guide profiles, wipers

- cleats, carriers, surfaces

- sidewalls, straight sidewalls

- mechanical joints and adjustments

Application

- conventional horizontal transport

- incline and decline

- bent "L" or "Z" conveyor

- trough design

- multi-track transfer

Field Application

- meat & poultry

- bakery & confectionery

- brick & roofing

- glass & ceramics

- cardboard & paperboard

Welding Tools

- welding sets

- welding presses

- mechanical joint tool