Timing Belts

Today's technology and advanced manufacturing processes place significant demands on increased productivity, capacity, speed, and quality. They are subject to permanent optimization and automation. They are becoming more efficient and safer. If your technology and processes require precise synchronization of position, speed and time, timing belts are the ideal modern solution. Coordinated horizontal transport, linear positioning, vertical lift, power, and force transmission are the main tasks of timing belts in a wide range of industries and applications.

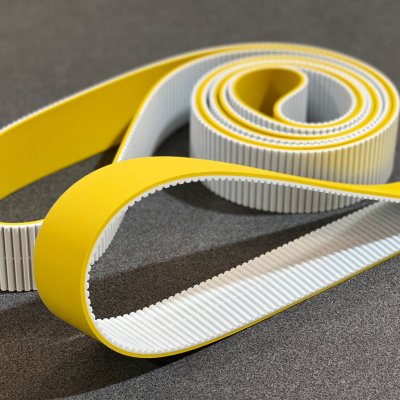

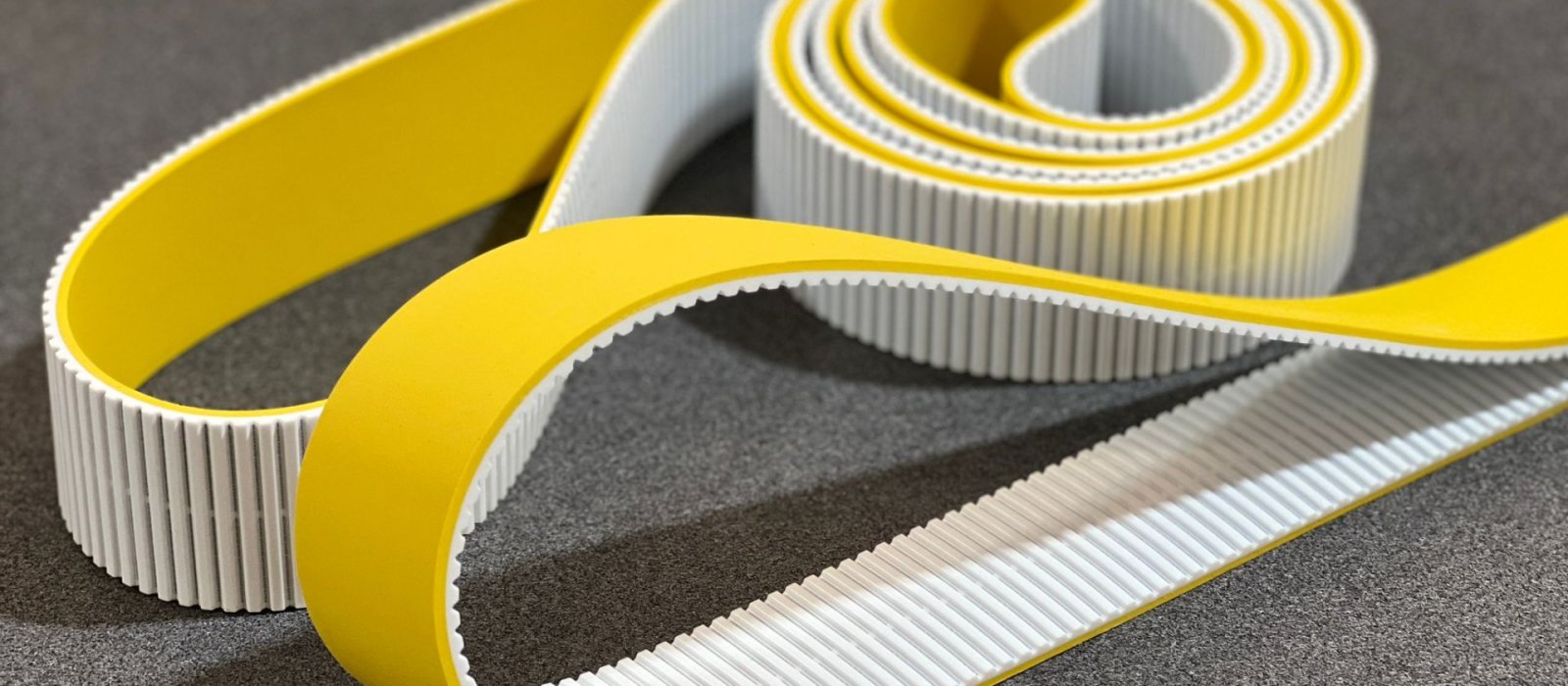

The production system enables the extrusion of linear timing belts in various designs. They consist of thermoplastic polyurethane (TPU), steel or aramid cords and polyamide (PA) fabric on the tooth and/or bottom. Our range includes a wide variety of standard linear timing belt pitches, including T5, T10, T20, AT5, AT10, AT20, HTD5M, HTD8M, HTD14M, XL, H, L, XH and many other variants. They can be supplied with or without an integrated or welded V-guide. We have timing belt versions available for direct food contact or in anti-static finishes. Welding technology allows each timing belt to be tailored to the individual requirements of the customer.

Linear Timing Belts - Open, Spliced

- Linear timing belts are manufactured, stored, and delivered as open rolls.

- The final product is an open linear metre-goods or endless spliced timing belt.

- The material of timing belts is abrasion resistant, dimensionally stable, and ensures smooth running.

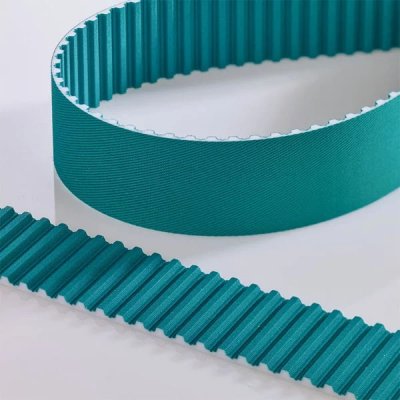

Flex-Timing Belts - Truly Endless

- Flex-timing belts do not have a weakened cross-section at the welded or mechanical joint.

- They are, therefore, the ideal product for high-speed, synchronous applications and high loads.

- They are available in required lengths from 800 to 24,000 mm, always in multiples of the tooth pitch.

Linear Timing Belts - Extra Wide

- These timing belts have been developed as an alternative to conveyor belts.

- They are only available in the trapezoidal tooth profile type T10 and L and have a maximum width of

600 mm. - The material of the supporting cords is aramid in a lightweight design inside the timing belt body.

Power-Transmission Timing Belts - Cast Sleeves

- A strong steel cord, wound into a spiral, cast abrasion-resistant polyurethane forms the combination and basis for dimensionally accurate, highly durable, strong, and powerful timing belts with a low degree of elongation.

- Due to their properties, they are used in many applications with high precision and speed requirements.

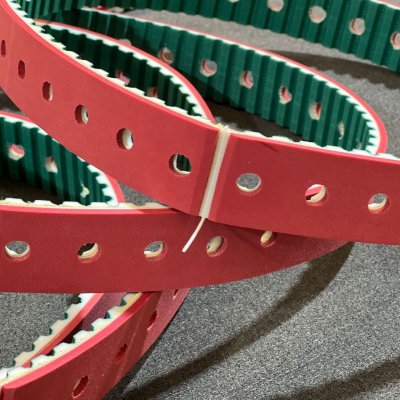

Engineered and Process Timing Belts

- Standard timing belts are semi-finished products which are equipped with accessories made of high-quality materials.

- By refinement, the required mechanical, physical and chemical properties are obtained.

- They help to meet the most demanding application requirements and provide solutions to meet individual needs.

Characteristics

- construction material thermoplastic polyurethane TPU, hardness 92°A

- material of tensile elements - steel cord or Kevlar (aramid fibre)

- supplemented with polyamide PA (nylon) fabric on the bottom, teeth or in combination

- PA fabric protects teeth, reduces friction, eliminates noise

- operating temperature resistance -20 °C to +80 °C

- very low maintenance

- high resistance to oils, greases, and hydrocarbons

- limited resistance to acids and alkalis

- resistant to moisture, UV, and ozone

Tooth Pitches and Profiles

- metric, trapezoidal type T2.5, T5, T10, T20

- metric, trapezoidal type AT5, AT10, AT20

- metric, round type HTD 5M, HTD 8M, HTD 14M

- imperial, trapezoidal type XL, L, H XH

Splicing

- finger splice

- mechanical pin joint

- combined plastic spiral joint

- mechanically between clamping plates

Accessories - Surfaces

- polyurethane

- PVC

- rubber

- silicone

- foam materials

- nonwovens

- fabrics

Accessories - Cleats

- machined plate, TPU hardness 92°A

- injection moulded shapes

- machined metal materials

- combined with threaded bushings

- combined with pins

- interchangeable, plug-in

- welded with visible weld

- welded without visible weld

- screwed

Accessories – Guiding

- integrated TPU V-guide K6, K13

- welded TPU V-guide K6, K8, K10, K13, K17

Accessories - Machining

- shape milling

- hole drilling, perforating

- shape cutting of cleats

- surface grinding

Accessories – Components

- standard pulleys

- customized pulleys

- toothed bars

- clamping plates

Application

- automation, robotization

- transport, handling

- cutting, positioning

- feeding, stepping