Wire Belts

Depending on the material used, wire belts can be used for a wide variety of different processes in which they meet a wide range of requirements. And of course, they are highly suitable for direct contact with foods. Their characteristic feature is the permeable and hygienic design, suitable for dipping, pouring, glazing, and spreading applications. They can withstand operating temperatures from -80°C to +280°C and are, therefore, suitable for drying and cooling tunnels, baking ovens, and soldering installations.

Wire belts are available in three product lines. ECO is an economical version for standard applications. The ELT range is an application with increased stability, higher strength, and long service life. Transport direction change is suitably addressed by wire belts designed for radius applications.

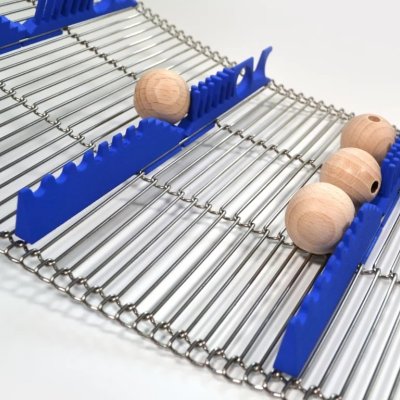

Individual requirements for the placement of raised shapes perfectly meet the expected function of point contact, precise, fixed positioning, and precise forwarding at points of transition.

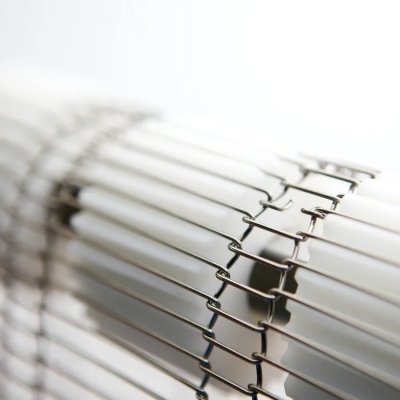

Wire Belts ECO

They are characterized by precise, maintenance-free belt movement and small bending radius. This means that even small products can be safely and easily transferred between production lines systems. The open design and structure ensure a free and hygienic passage of liquid media and hot and cold air.Wire Belts ELT

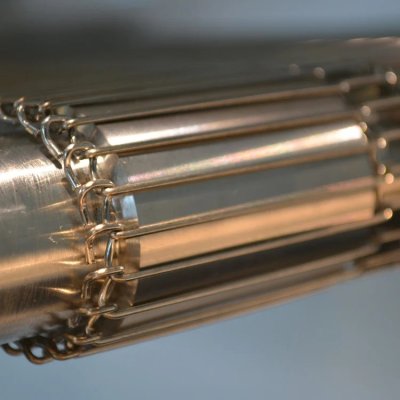

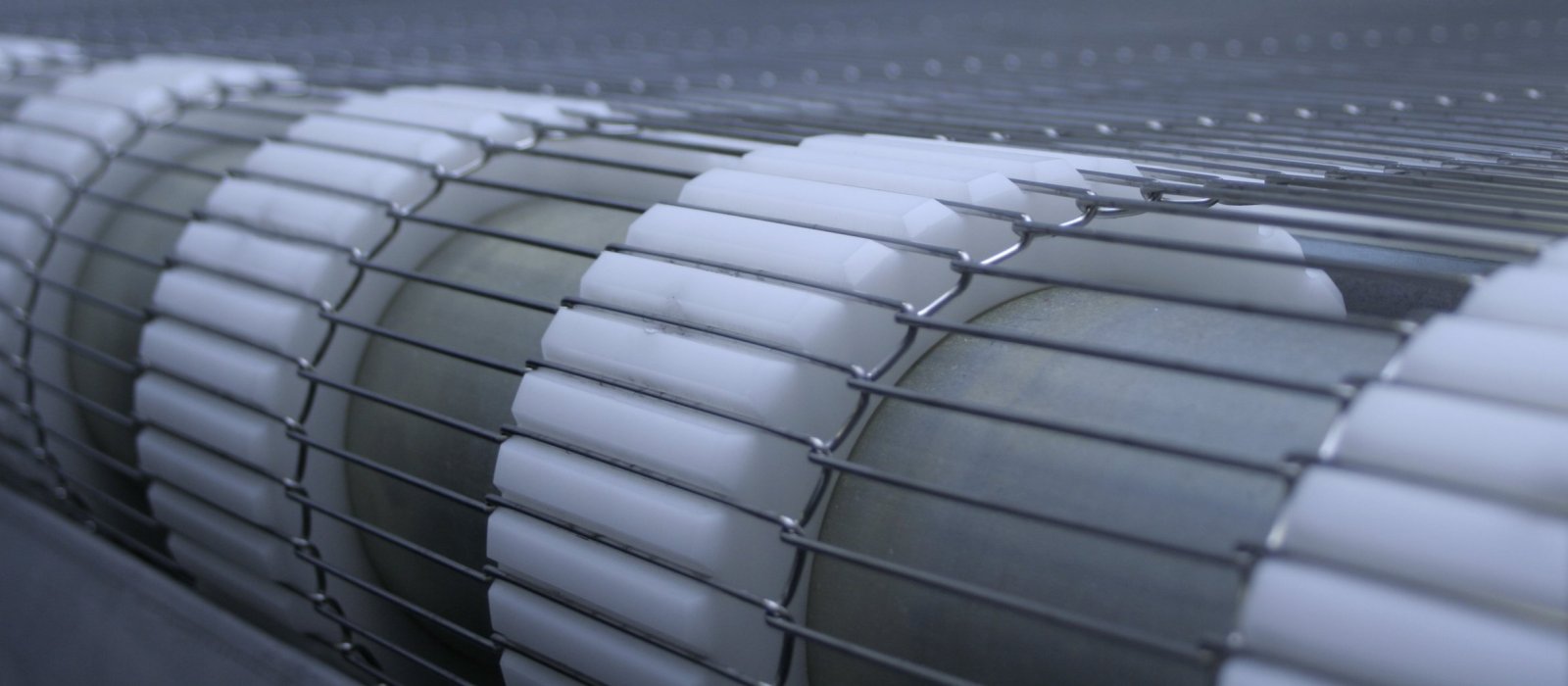

Compared to a standard wire belt, they are characterized by a significant bond density, with more multi-knotted points leading to increased stability and higher force absorption. The design of the knot points allows for user-friendly joining options into an endless belt, or the possibility of simple repair or replacement.Wire Belts - Radius

Curve belts are suitable for transporting light to medium-weight products in all industries. They can be used to equip curve transfers from 30° to 180°. The design principle of the curve belts is the regular, constant increase of the wire weave spacing.Characteristics of ECO

- permeable, hygienic design

- lightweight, flexible design

- centring self-regulating movement

- small bending radius

- standard, economical solutions

- suitable for direct food contact

- material - stainless steel or spring steel

- belt width up to 4,000 mm

- temperature interface from -80 °C to +280 °C

- conveying speed up to 15 m/min

ELT Characteristics

- fast, hygienic joining

- robust construction

- long service life

- elimination of downtime

- overcoming long distances

- suitable for direct food contact

- material - stainless or spring steel

- belt width up to 4,000 mm

- temperature interface from -80 °C to +280 °C

- transport speed up to 30 m/min

Curve Characteristics

- high-temperature resistance

- permeable, hygienic design

- lightweight, flexible design

- conveying angle 30° to 180°

- standard inner radius 350/406/650/800 mm

- standard belt width 406/600/610/864/1,000/1,270 mm

- another radius and width on request

- large width can be achieved by splitting the belt

- material - stainless steel or spring steel

- temperature interface from -80 °C to +280 °C

Accessories

- drive elements

- return elements

- polyamide cleats

- raised shapes

- guide chains

Application

- continuous baking ovens

- continuous fryers

- cooling, drying tunnels

- dipping, coating lines

- laminating, sprinkling lines

- degreasing and cleaning equipment