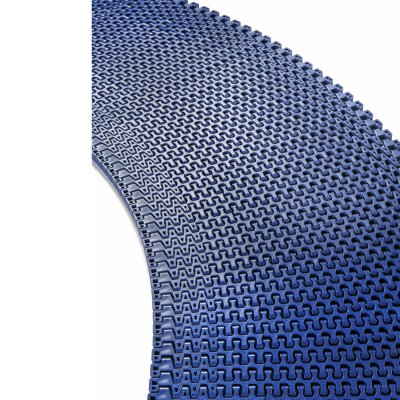

Modular Belts

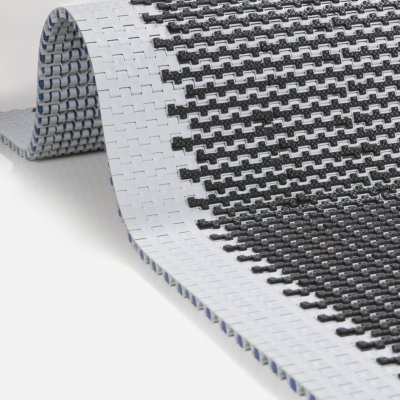

Modular conveyor belts form a flexible conveyor system used in a variety of industries. The belt is made up of plastic modules folded into a brick pattern.

The modules are connected by pins. Thanks to its modular concept, they offer easy assembly, and adjustment and ensure an efficient production process. Plastic modular belts are classified as direct, positive drive products. Sprockets transmit force and motion preventing possible slippage. At the same time, the sprockets act as a centring function and help the modular belt to self-regulate. The belts do not require maintenance and the modular system is designed to minimise losses and downtime.

Modular conveyor belts are offered in a variety of materials to meet specific operating requirements and environmental conditions. The choice of material can significantly affect the overall performance, durability, and cost of the conveyor belt. Standard base materials are available for the vast majority of applications.

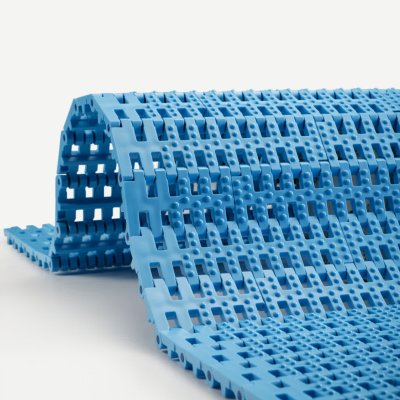

Flexibility and Assembly

The variable assembling of the modular belts in length and width allows adaptation to the requirements of transport systems. Thanks to the structure of the components and modules, they are quickly assembled and replaced.

Wear and Lifetime

They are made of durable plastic or metal materials. Their characteristic feature is robustness. With the right choice of components and the right technology, they are very wear-resistant and have a long service life.

Maintenance and Cleaning

Maintenance and cleaning are effortless thanks to the modular system. They guarantee a minimum of downtime and losses in the production process. Automatic cleaning systems contribute to efficient use of the time required for the specified hygiene steps.

Production and Processes

Thanks to their modular concept, they can quickly adapt to process and product changes on the production line and optimize production flow and process.

Security

Optimally designed modular belts include safety features and measures that are an important factor for worker and product safety.

Compact Design

Modular belts can be used efficiently even in confined spaces and optimize the layout of production areas.

Cost-effectiveness

High productivity, low maintenance costs, wear resistance and long service life make modular belts a highly cost-effective solution.

Material Choice

Polypropylene /PP/

- temperature resistance from +5° C to +80° C

- most commonly used material for a large number of conveying applications

- excellent chemical resistance

- suitable for direct food contact

Polyethylene /PE/

- temperature resistance from -70 °C to +60 °C

- suitable for low-temperature applications

- good shock-load resistance

- excellent chemical resistance

- suitable for direct food contact

- not suitable for abrasive environments

Polyacetal /POM/

- temperature resistance from -38°C to + 90°C

- in humid environment, the temperature resistance varies from -35 °C to +60 °C

- material suitable for demanding applications

- excellent mechanical properties - high strength, low friction coefficient

- not suitable for chemically aggressive environment

Wide Possibilities

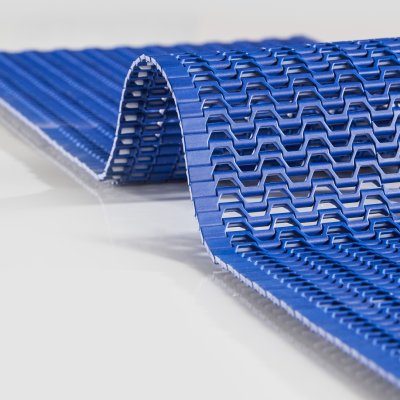

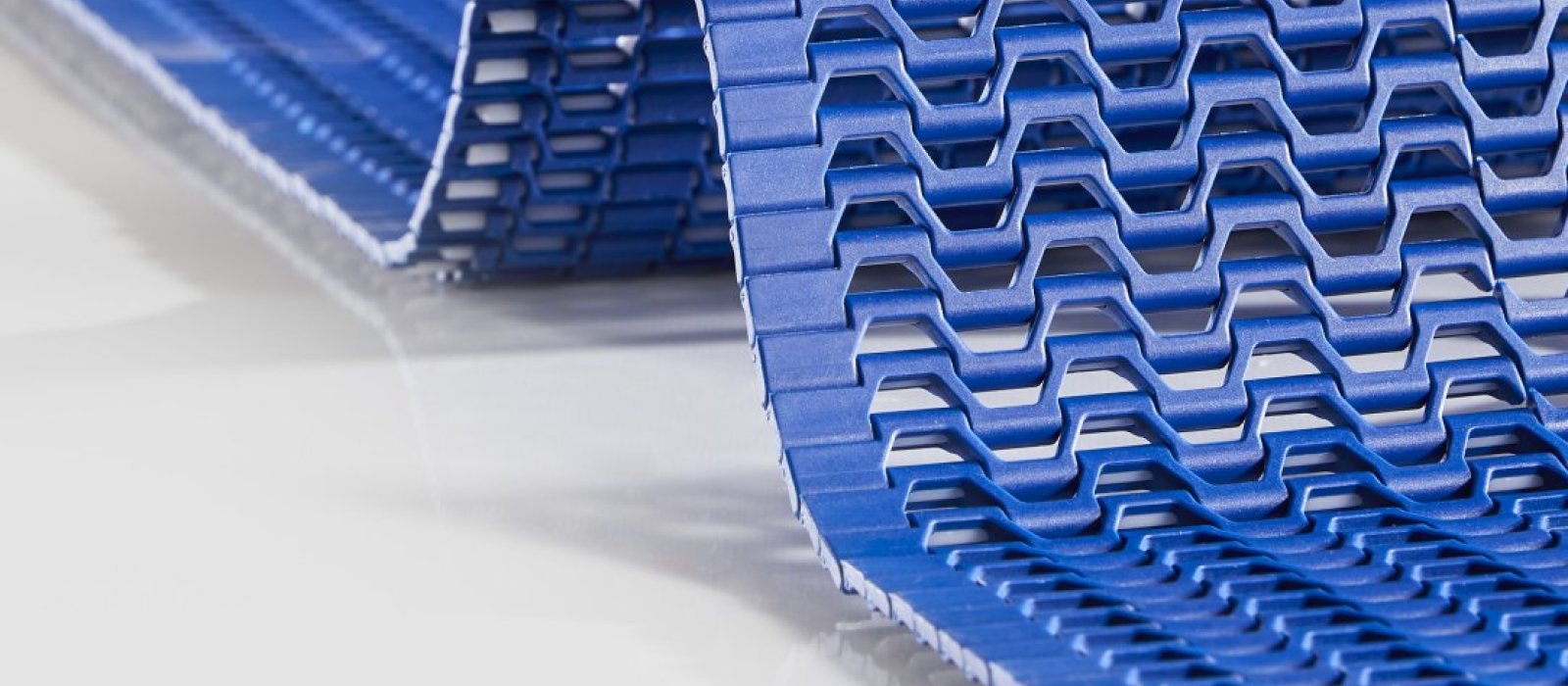

Direct Movement

- series pitches 0,3"/8 mm, 0,5"/12,7 mm, 1"/25,4 mm, 2"/50,8 mm

- open and closed surface

- long life, low wear

- easy maintenance and cleaning

- without lubrication and tensioning needs

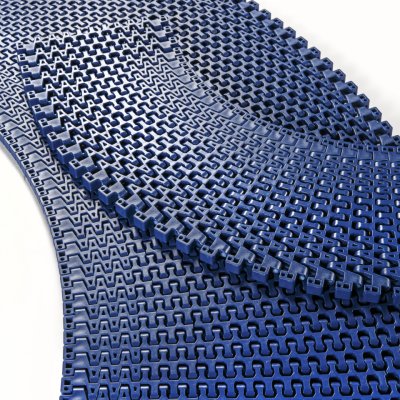

Radius Movement

- series pitches 1"/25.4 mm, 2"/50.8 mm

- open surface

- minimises the number of transitions

- reliability of transport of small products

- optimum durability x load ratio

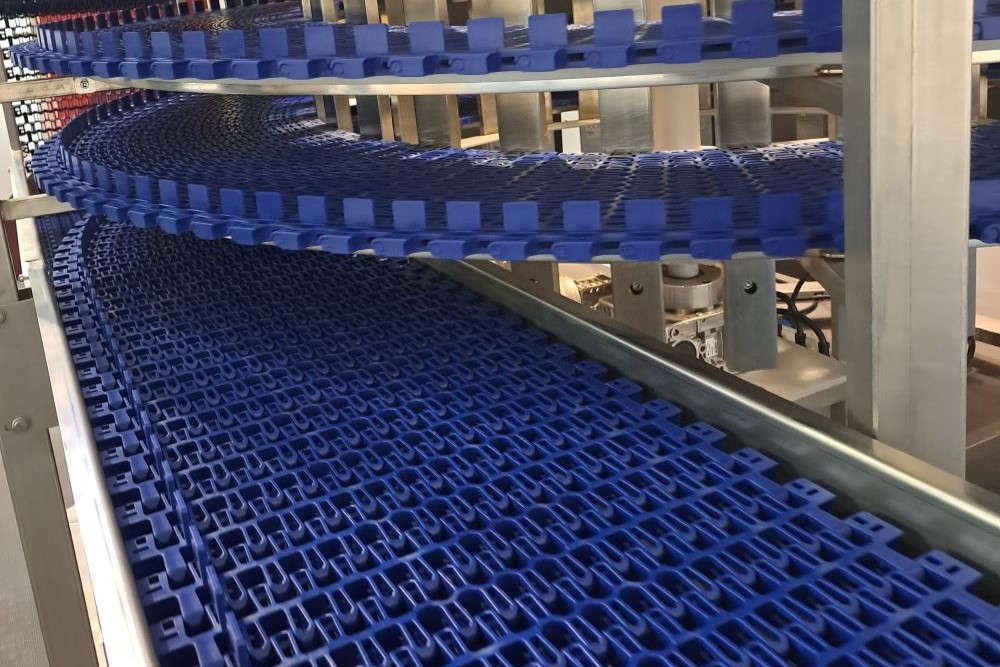

Spiral Movement

- series pitches 1"/25.4 mm, 2"/50.8 mm

- cooling, freezing, and dough-rising applications compared to metal belts

- low weight, excellent permeability, minimal contact

- compactness, space-saving

Accessories

- sprockets, support rails

- flights, buckets

- sidewalls, dividers

- ridge transitions

Plastic Chains

- direct movement, radius movement

- low weight compared to metal alternatives

- robust construction, high strength

- low noise, shock-load resistance

- chain segment replacement, long life