Industrial Machines

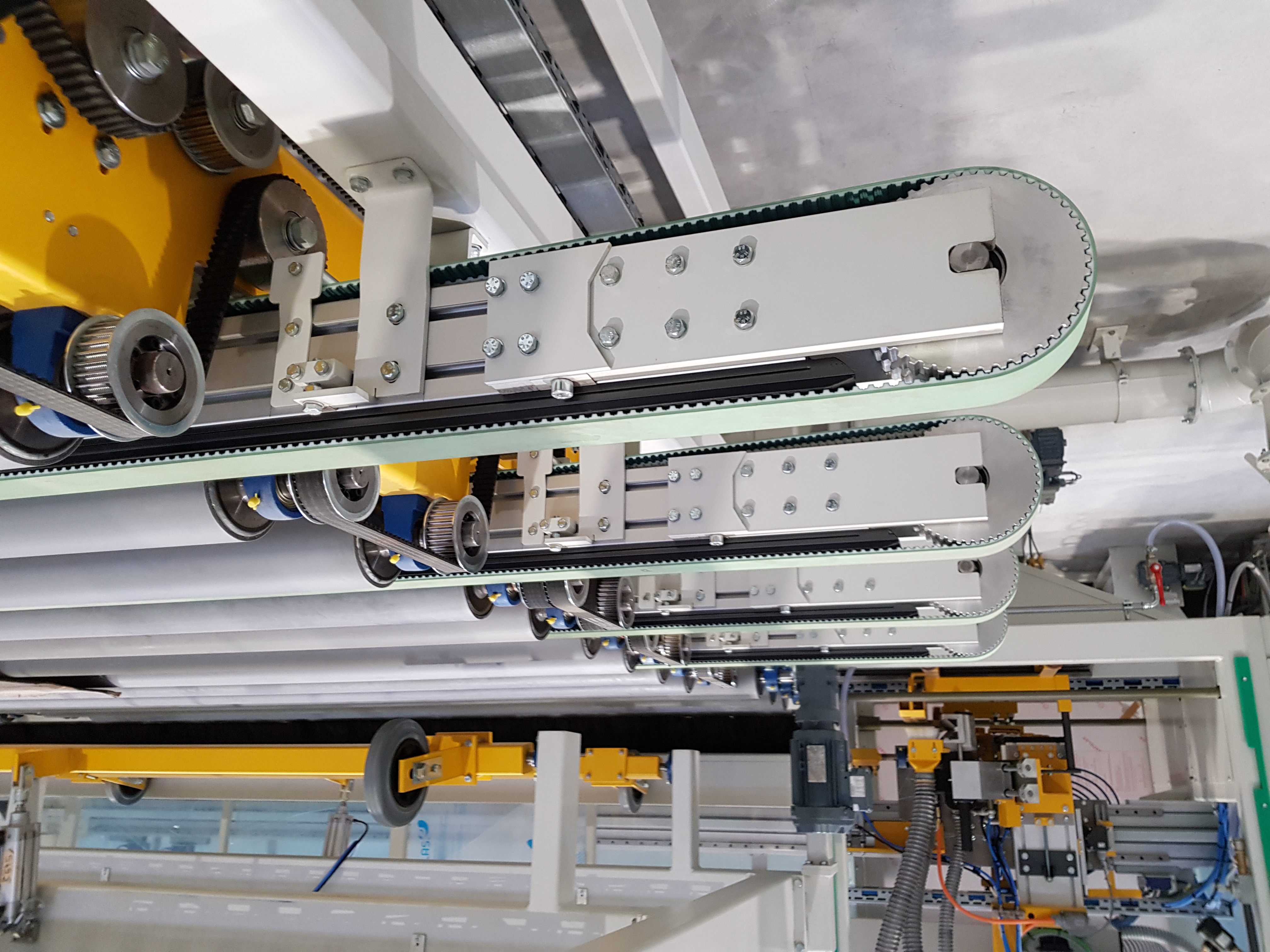

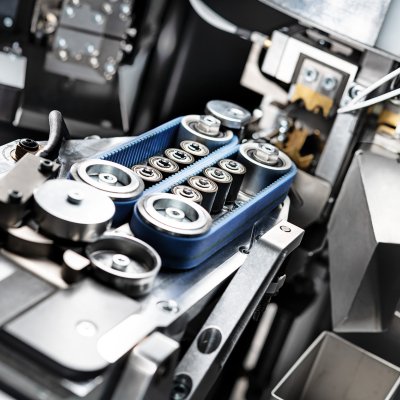

Engineering produces a range of machines and equipment for most other industries. Modern machines are able to satisfy the requirements for flexibility and individualisation of semi-finished or finished products. At the same time, they achieve the efficiency, speed and productivity typical of mass, serial production. Production technology, speed and automation create room for designers and engineers to integrate components such as engineered and process timing belts or high-performance flat belts. Depending on the degree of logistics and robotization, we encounter interconnected peripherals as a fixed component of the machine. These are conveyors with the function of feeding semi-finished products or an output of final products. The function of the conveying element is often performed by conveyor belts, modular belts or timing belts.

Examples of Integration or Peripheral Applications in Industrial Sectors

- bakery & confectionery – deck oven loaders

- meat & poultry - batching, portioning, shaping, and sealing of sausages and meat products

- meat & poultry - meat separation by drum separator

- panels & boards - continuous, tower presses and preforms

- panels & boards - wide belt sanders

- paper & printing – flex-printing machines

- boxes & bags - folding, glueing, printing machines

- parts & components - automatic cable processing (measuring, cutting)

- VFFS vertical packaging machines – pull-down belts, feeding conveyors